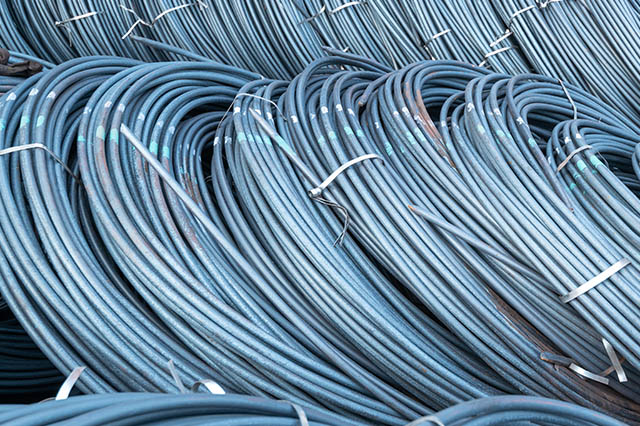

Wire rod is the smallest section size in hot rolled section steel. In China, hot rolled round steel with a diameter of 5 ~ 9 mm and a total of eight specifications is called wire rod. Wire rod is also called wire rod because it is delivered in coils. The concept of wire rod in foreign countries is slightly different from that in China. In addition to circular section, it also has other shapes, and its diameter is inconsistent due to different demand and production technology level. According to different rolling mills, it can be divided into high-speed wire rod (high-speed wire rod) and ordinary wire rod (ordinary wire rod).

Wire rod is generally made of ordinary carbon steel and high-quality carbon steel. According to the steel distribution catalogue and different purposes, the wire rod includes ordinary low-carbon steel hot-rolled disc bar, high-quality carbon steel disc bar, carbon electrode disc bar, Quenched and tempered thread disc bar, steel wire rope disc bar, piano steel wire disc bar and stainless steel bar.

According to the chemical composition of steel, wire rod can be divided into two categories: one is carbon steel, which can be divided into low carbon steel, medium carbon steel and high carbon steel according to the carbon content; Second, alloy steel. At present (1992), the steel types of wire rod are mainly ordinary low carbon steel, high-quality carbon steel, welding rod steel, steel wire rope steel, stainless acid resistant steel, heat-resistant steel, rolling bearing steel, etc. According to the section shape, the wires are round, square, oval, trapezoid and special-shaped. There are few squares, less special shapes, and generally more circular sections.

There are two main uses of wire rod: one is for building materials; Second, it is used as raw material for wire drawing.

Wire rod for building materials, including ordinary low carbon steel, high-quality carbon steel and carbon spring steel. The varieties are round and threaded. The specifications with a diameter of 6 ~ 25 mm are most widely used, and those with a diameter of 28 ~ 32 mm are also often used. As a building material, the wire is required to ensure the chemical composition and weldability, and the physical properties are required to be uniform and stable, so as to facilitate cold bending, cold drawing and cold drawing. Wire rods of various specifications and diameters used in construction engineering are expected to be delivered in coils, so as to cut arbitrarily according to the length, so as to avoid waste.

Although there are many kinds of steel wires as wire drawing raw materials, there are only round ones. In order to reduce the drawing times, the diameter is generally 5 ~ 9 mm, and wire with diameter greater than 10 mm is also used for special purposes. As the wire drawing raw material, it is required to ensure the uniformity and stability of chemical composition and physical properties, the metallographic structure should be sorbitic as much as possible, the size should be accurate, the surface should be smooth, and the iron oxide scale should be thin, which is conducive to removal.

In general, wire rod has a wide range of uses and plays an important role in all sectors of the national economy. Some wires can be used directly after rolling, mainly for reinforcement of reinforced concrete and welding structural parts; Some are used as reprocessing raw materials after reprocessing. For example, it is drawn into various steel wires, twisted into steel wire rope, or woven into steel wire mesh; Rivets formed by hot forging or cold forging; After cold forging and rolling into bolts, and after various cutting and heat treatment into machine parts or tools; The spring is made by winding and heat treatment;

As a wire for construction, it must ensure chemical composition and weldability, have certain mechanical properties and be uniform and stable, so as to facilitate cold bending and bearing. The wire used for wire drawing shall ensure uniform and stable chemical composition, metallographic structure and mechanical properties. The metallographic structure shall be sorbite as far as possible to reduce the annealing times during cold drawing. In addition, the specifications and dimensions shall be accurate, and the diameter is generally less than 12mm. The surface shall be smooth, the iron oxide scale shall be thin and easy to be washed off by acid, and the surface shall be free of defects such as ears and folding.

© 2022 TK Steels. All Rights Reserved.